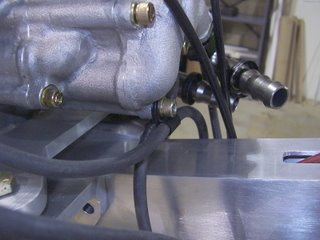

Below are some pictures of my mounted choke lever. I bought the choke lever that Hpower sells for the HKS engine but the lever it comes with does not fully actuate the chokes. I was also having trouble finding a location to mount the supplied lever due to the cable being too short (I even bought Hpower's long choke cable assembly).

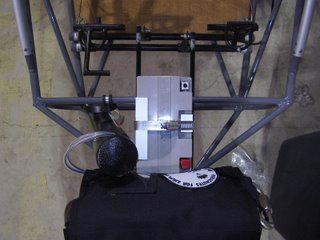

I ended up hacking off the supplied lever and replacing it with a lever from a bicycle store. This lever is friction based and mounted nicely to my flap lever. I considered mounting the choke lever to one of the supports under the seat but the lever's built in mounting hardware did not allow it to be rotated and would only easily fit a 1" diameter tube. I needed to use a wire stop at the lever since I do not have a cable of the exact length. I could have one made now that I know what the length is. Hmmmm... That would clean up the wire end that is protruding from the lever and remove the need for the wire stop.

Placement of the choke lever was tight due to interference with the throttle level and the arm-rest. I made sure the choke cable would not interfere with the motion of the flap lever. The third picture shows the lever fully actuated with full flaps.