After I finished with the rudder, I installed the elevators.

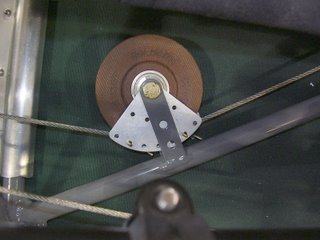

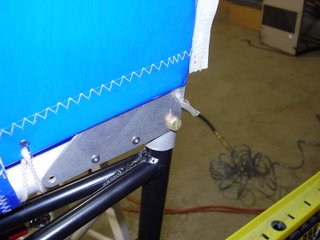

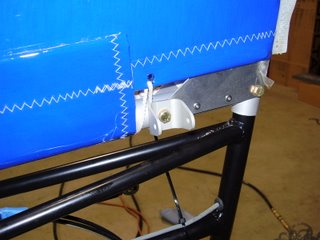

These went on without much difficulty. Each elevator has two hinges and a elevator horn for actuation. I needed to rotate one of the elevator horns because I had installed it backwards.

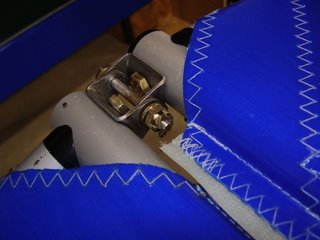

Once I installed the hinge and horn bolts, I installed the necessary lock rings and cotter pins. I also lubricated the hinges with a spray on teflon lubricant.

I also installed the black plastic caps on the outside ends of the elevator's aluminum tubes. The assembly manual calls for the caps on the inside ends of the tubes but I didn't see the need.