Belly Pan Fabric - 1 hour (350 Total)

I was planning to glue my green fabric to the inside of my belly pan sheet metal today but I had forgotten to buy glue. All I was able to do was rough cut my fabric to the proper sizes and mask off the portions of the sheet metal I didn't want glue to adhere to. I'll pick up some glue tomorrow.

By the way, I'm at 350 hours; shouldn't I be done already!?

Sunday, September 10, 2006

Belly Pan Cover - 0.5 hours (349 Total)

One of the other things I did today was prep the Belly Pan Cover. This plastic piece covers the elevator push pull rod that protrudes from the bottom of the plane.

The Pan come rough cut from Rans and needs to be trimmed to the proper size. This is similar to the plastic ribs that are used in the horizontal and vertical stabilizers. I used my dremel tool to cut and smooth the pan into the proper shape. I also roughed up the inside so I can paint it. I use a can of spray paint to paint the inside of the pan prior to installing it into the plane.

One of the other things I did today was prep the Belly Pan Cover. This plastic piece covers the elevator push pull rod that protrudes from the bottom of the plane.

The Pan come rough cut from Rans and needs to be trimmed to the proper size. This is similar to the plastic ribs that are used in the horizontal and vertical stabilizers. I used my dremel tool to cut and smooth the pan into the proper shape. I also roughed up the inside so I can paint it. I use a can of spray paint to paint the inside of the pan prior to installing it into the plane.

Cowl Clean Up - 0.5 hours (348.5 Total)

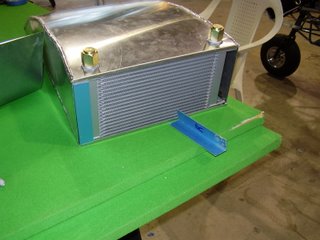

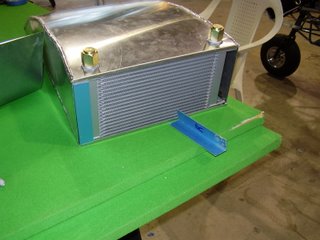

My oil cooler cowl needs a little more work prior to painting. The front corners need to be rounded off to prevent them from damaging the wing fabric and the gaps in the rear need to be filled. I also need to secure the cooler inside the cowl.

I think I will have the welder tack weld the cooler inside the cowl. This will be an easy alternative to bolting or riveting it in to place. Since the oil cooler is trapped inside the cowl, the cowl will need to be cut open to remove to cooler anyway.

I was able to round over the front corners of the cowl with a pair of snips and my dremel tool.

For the holes in the back side, I cut some aluminum angle to length that will rivet nicely inside the cowl. I considered having a few pieces welded into place but I think this would be difficult with the gaps that are present. I will rivet these into place once the welder has secured the cooler.

My oil cooler cowl needs a little more work prior to painting. The front corners need to be rounded off to prevent them from damaging the wing fabric and the gaps in the rear need to be filled. I also need to secure the cooler inside the cowl.

I think I will have the welder tack weld the cooler inside the cowl. This will be an easy alternative to bolting or riveting it in to place. Since the oil cooler is trapped inside the cowl, the cowl will need to be cut open to remove to cooler anyway.

I was able to round over the front corners of the cowl with a pair of snips and my dremel tool.

For the holes in the back side, I cut some aluminum angle to length that will rivet nicely inside the cowl. I considered having a few pieces welded into place but I think this would be difficult with the gaps that are present. I will rivet these into place once the welder has secured the cooler.

Subscribe to:

Comments (Atom)