Today I finish rigging the flaps. I attempted to do this several weeks ago but was having difficulty because either the flaps would be too high or too low. Rans's suggestion for alleviating this issue was to trim the excess thread off of the teleflex cable. I trimmed 5/16" off of both teleflex cables above the cockpit. This allowed for only a couple of threads to remain before the teleflex bottoms out onto the bolt in the Insert Nut.

Rans also told me to set the teleflex retainer bracket so the angle was towards the front. Trimming the excess teleflex thread and having the bracket in this orientation only made the problem worse. By rotating the teleflex retainer bracket around, the problem was reduced but not solved.

I then trimmed off 3/16" of the left teleflex cable at the flap end. This turned out to be unnecessary because the Flap Lever Teleflex Cable was still adjusted. Luckily I didn't trim off too much. I did not trim the right cable.

I readjusted the Flap Lever Teleflex Cable so it was fully bottomed out. I then built a jig to allow me to accurately set the flap and aileron droop out of some plywood (actually OSB). This jig will hook onto the front spar of the wing and allow me to check droop of the flaps.

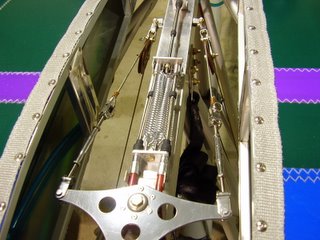

Once the flaps were adjusted, I safety wired the teleflex retainer brackets within the wings and placed the "safety brackets" above the cockpit.

I then trimmed the wing fabric around the flap teleflex cables to prevent rubbing. These did not come out as clean as I had hoped.

Here are pictures of the safety wire used on the teleflex retainer brackets within the wings.