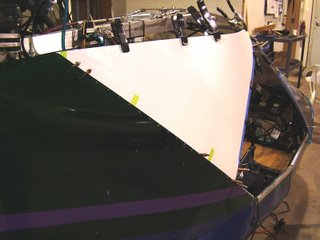

The last thing I did today was install the window.

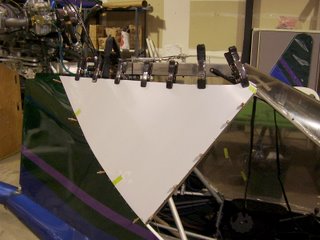

I fitted the window the same time I fitted the windshield so some of the photos below show the windshield prior to riveting.

The window former (aluminum tube) needed to be fitted at the same time as the window.

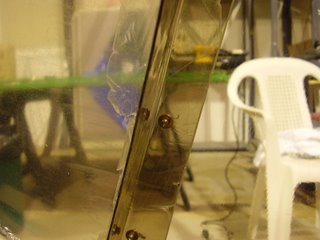

The window installation was pretty straight forward but I did have an issue with some of my rivet holes not lining up with one of the aluminum tubes. Because the protective plastic on this sheet of Lexan was opaque, I wasn't able to see that the predrilled holes in the sheet metal side panels were too high on the tubing. The second photo from the bottom shows how two of the holes elongated. I had drilled these two holes without knowing there was a problem. While drilling the third hole, I could feel the drill bit slip. This caused some severe marring of the aluminum tube. There isn't anything I can do about the marring but I was able to use some extra long rivets on the first two holes. The normal rivets would not have secured properly in the elongated holes.

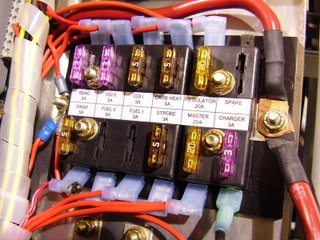

The last photo shows the gusset placed on the window former. This was installed after the window was riveted in to place. The gusset on the other side (between the window and window former) was installed at the same time the window was fitted and installed.