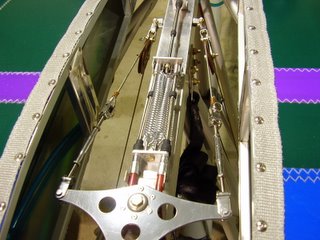

After many hours of holding the oil tank in different positions around the plane trying to find the optimum location, I finally decided to mount it on the middle cabane on the left side.

This location will give me easy access to the take from the door allowing easy filling. It will also allow easy draining since there is plenty of clearance between the drain plug and any obstacles. Since it is mounted between the left cabanes and left wall, it is making use of space that would normally be wasted. The tank needed to be oriented just right so it doesn't come in contact with the planes skin or the aileron cable.

A few negatives of this location are: The sight tube will be difficult to see but I may be able to see it from outside the plane through the left window. This location is also close to my head. If there is considerable noise from the sloshing of the oil, I may have trouble with keeping my bladder comfortable!

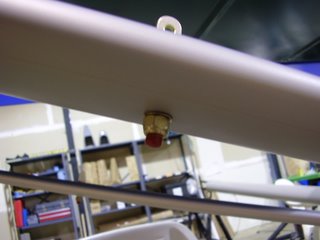

I mounted the oil tank using 1" cushioned wire clamps. Placing two clamps on the middle cabane but in opposite facing directions allowed me to compensate for the left-right angle the cabane sits at. I used a piece of aluminum angle mounted from the tank bracket to the rear cabane to keep the tank from rotating around the middle cabane.

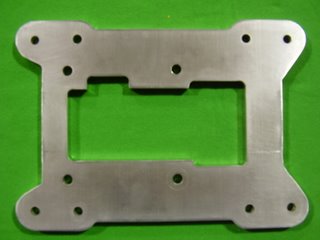

I needed to attach the tank's mounting bracket in a funny fashion to get the fittings to face the rear of the plane.