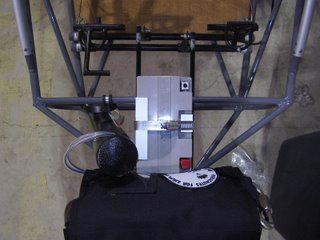

Today I mounted the BRS activation handle and right seatbelt.

The BRS activation handle is mounted to the same bracket that the right side seatbelt mounts to.

I connected the activation cable to the rocket so it is now live! I replaced the safety pin with a 3/16 bolt so I didn't have to worry about the safety pin and warning label being inadvertently removed.

I used locktite on the two bolts that hold the rocket mount, on the threaded cable connection to the rocket, and the clasp that holds the rocket bridal to the parachute.