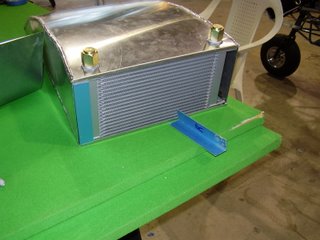

My oil cooler cowl needs a little more work prior to painting. The front corners need to be rounded off to prevent them from damaging the wing fabric and the gaps in the rear need to be filled. I also need to secure the cooler inside the cowl.

I think I will have the welder tack weld the cooler inside the cowl. This will be an easy alternative to bolting or riveting it in to place. Since the oil cooler is trapped inside the cowl, the cowl will need to be cut open to remove to cooler anyway.

I was able to round over the front corners of the cowl with a pair of snips and my dremel tool.

For the holes in the back side, I cut some aluminum angle to length that will rivet nicely inside the cowl. I considered having a few pieces welded into place but I think this would be difficult with the gaps that are present. I will rivet these into place once the welder has secured the cooler.